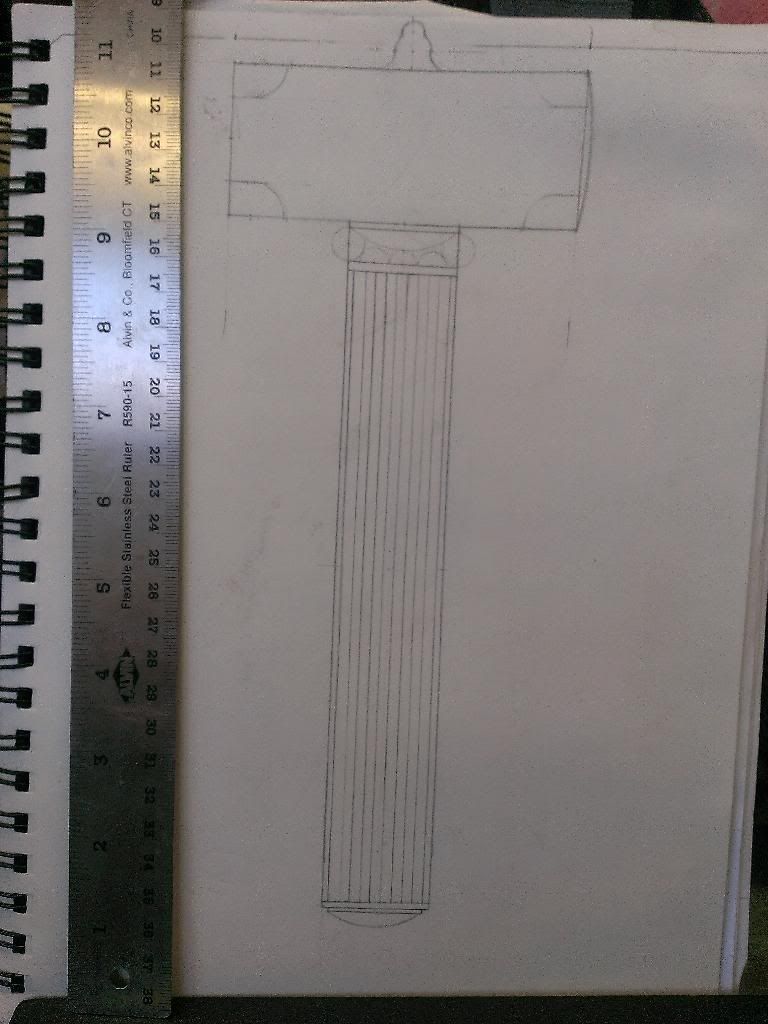

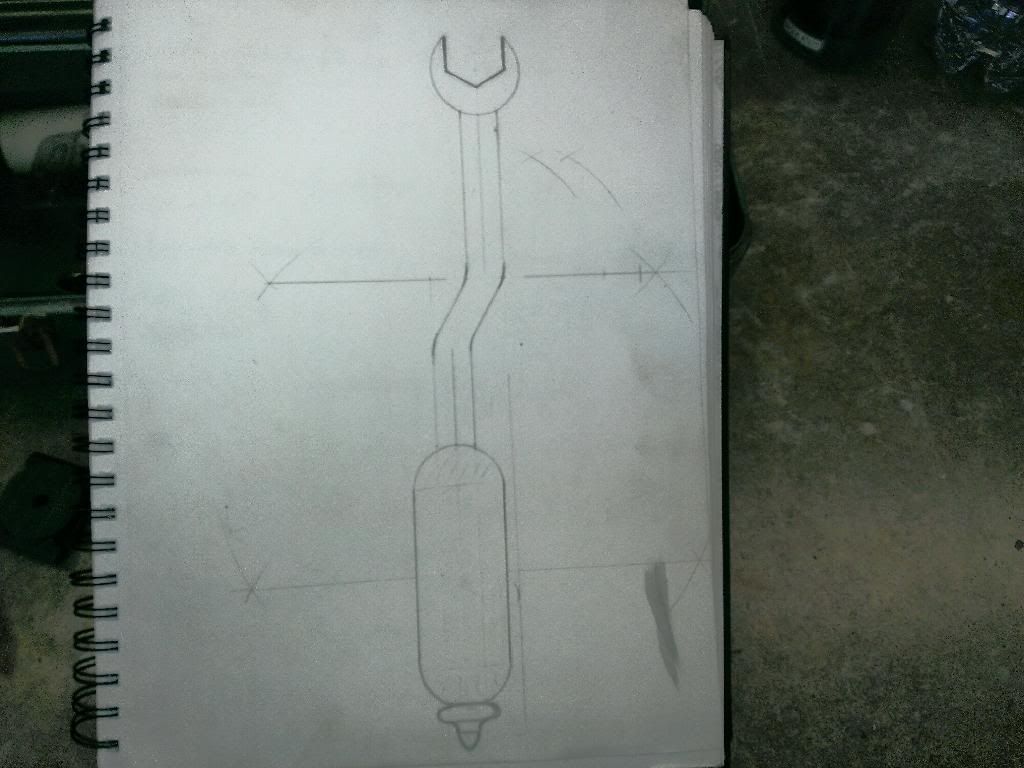

These aren't exact blueprints, just scaled examples of where the project is headed.

Since I've had a hard time finding high carbon steel in my area I used a local metal reseller for most of my steel. She had some nice new 4340 available in bars for $1.50/lb, so I cut that into coupons and tacked them together without any fill rod, and forge welded it into one block.

My first "forge" was a stack of fire bricks that I pointed my O/A torch into, I have since built a more respectable forge.

I built this small press to help with forging and forge welding, it uses a 20 ton air-over-hydraulic cylinder. It's a bit slow and I'll definitely build a better one when funds allow.

For the wrench I used a car coil spring, straightened and upset on one end. I used an air chisel to cut a slit in the upset, then opened it and wrapped it around a rod (sorry, no pics). Then I filed the open box by hand to fit a 3/4" bolt.

Then I forged a taper on the other end and cut 1/4"-20 threads, this is how the handle will be affixed.